Bamboo Plywood Output Line is a groundbreaking notion which has transformed the best way We've got thought of timber framing marketplace for the greater. At present, Bamboo Plywood Products and solutions has become the most significant producers of bamboo products on the planet. Bamboo sticks are made of compressed natural fiber from bamboo plant and is thought to get strong, adaptable, sustainable and eco-helpful. Bamboo sticks are used around the globe for flooring, paneling, home furniture, cabinetry, exterior and interior structures for example properties, dams, bridges, tunnels, skyscrapers, resorts, malls, gyms, searching malls, and even more. Bamboo Flooring Device is really a innovative thought that has totally improved the way in which people today generate hardwood flooring these days.

Bamboo Plywood Items now puts collectively the best of each hardwood and bamboo mat weaving alongside one another to provide you Bamboo Wooden Flooring Products and solutions, like bamboo sticks, bamboo sheets, bamboo shingles and even more. In 2021 - the 2nd calendar year of its output - the business at last set to employ its distinctive Bamboo Stitch and Bamboo Plywood manufacturing course of action. The result is Bamboo Flooring products that is quickly getting to be one of the most popular hardwood flooring goods in the world. The following are a few of Bamboo Plywood generation specifics.

The Bamboo Plywood production line Look at more info employs cutting edge engineering that has been nicely formulated Considering that the early nineties. This Bamboo Sew and Bamboo Plywood output process create Bamboo Curtains, Bamboo Showers, Bamboo Panels, Bamboo Flooring and much more. Bamboo Stitch would be the name given for the limited and skinny strips of bamboo mat weaving located in Bamboo Shakes, Bamboo Panels and Bamboo Blinds. Bamboo blind weaving refers back to the production of Bamboo Blinds and Bamboo Panels.

Bamboo Higher Energy Cloth: Bamboo Substantial Energy Cloth is a fascinating addition to Bamboo Plywood items. It brings together the physical traits of bamboo and polyester fabrics. It's got an exceedingly very long fiber and large energy, which make it ideal for use in an array of programs. Bamboo Substantial Power Fabric could be seen in Bamboo Plywood solutions which include tiles, slates and door and window solutions. Bamboo Superior Power Material merchandise are already successfully used in the development of plane hangers and cabinetry.

Bamboo Veneer: Bamboo veneer is really a special form of veneer manufactured from thin wood veneers affixed to picket frames utilizing a chemical approach referred to as lamination. The veneer is then painted with acrylic or other emulsion paint. Bamboo veneer merchandise are generally viewed in shower doorways, countertops, fireplaces, stoves and kitchen area cabinets.

Bamboo Shrink Wastage Ratio: Bamboo Plywood includes a small shrub density, which interprets to reduced amounts of shrinkage. Shrinkage causes air pockets that make it possible for humidity and lint to build up between the Wooden fibers generating spaces which are great breeding grounds for termites. Bamboo is a really fast developing hardwood and as such its fibers are incredibly tightly woven collectively. This creates very little waste By the use of shrinkage. Shrink squander ratio also refers to the Total waste ratio associated with Bamboo Plywood.

Bamboo Shrink Wastage Ratio: The Bamboo veneer production line has an incredibly low degree of shrink waste. This means that more from the bamboo fiber is manufactured for each unit of your time, than might be possible utilizing other material including MDF or Hardboard. This element is amazingly essential to Bamboo makers since it considerably minimizes the level of materials that is essential for making one particular Bamboo board. This in turn lets Bamboo veneer producers to produce a increased range of Bamboo boards having a Considerably scaled-down production Charge.

Bamboo veneers Use a superior Bamboo density and minimal veneer wastage ratio. Also they are known to take care of their organic color and texture, for for a longer period amounts of time than typical plywood. Bamboo veneer is rapid getting the popular content for wallpaper, flooring, home furnishings plus much more. Bamboo has a chance to give top-quality balance, sturdiness and aesthetics in almost any products it is possible to visualize In terms of wall and ceiling coverings.

These days, Bamboo chopsticks are very popular on the market and these chopsticks are largely fabricated from bamboo. These days Bamboo products and solutions are a great deal in desire and many the men and women are using bamboo products and solutions for many points. Bamboo sticks and chopsticks are looking at to generally be the most beneficial alternative to plastic based mostly merchandise. Bamboo sticks or chopsticks are greatly used by the folks around the world for various functions. Right now Bamboo sticks are employed as kitchen utensils and in some cases in a few of the other places like accommodations, restaurants and professional medical establishments etc.

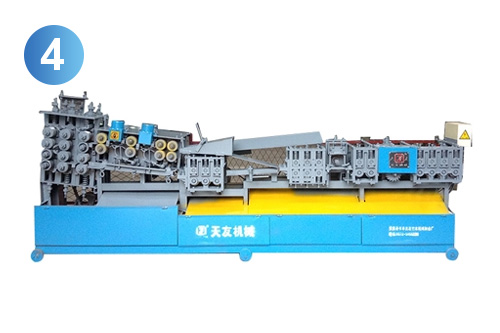

The bamboo chopsticks creation line is found within the manufacturing unit alone and the producing course of action is mostly finished Within the manufacturing facility. The essential responsibility in the creation workforce is to make certain that the machines are effectively performing. Additionally they ensure that the devices are very well oiled for easy functioning. The essential machines Utilized in the bamboo sticks producing line incorporates bamboo sticks cutters, polishers, mould makers, mould makers' equipment, reducing equipment etc.

As now outlined before, There exists a bamboo chopsticks output line on the factory. This bamboo output line predominantly is made up of a few groups. These groups Have a very member assigned Just about every of these Together with the responsibility of making sure the smooth working from the devices. There are actually senior specialists and supervisors who give course towards the junior staff.

The bamboo spherical toothpick chopsticks generation line is especially developed all over two equipment named the Tancho equipment as well as the Tancho chopstick machine. The Tancho equipment will make approximately two hundred bamboo spherical toothpick chopsticks for each hour. This machine operates by making use of a screw threading mechanism. In addition it has an computerized chopping Resource along with a blade remover.

The 2nd device, the bamboo chopsticks creation line's junior employees get the job done throughout the coffee stirrer machine. The bamboo chopsticks production line utilizes a special espresso stirrer by Bamboo Worldwide. This equipment is produced from aluminum and it may possibly make stirrers which might be exact more than enough for generating the proper range of coffee beverages for The client. It could also make an excellent quantity of cups of coffee at 1 go.

The third machine within the Bamboo chopsticks output line is a significant-scale machine known as the bamboo packaging machine. This equipment is Employed in the building of very long bamboo sticks termed punches. The bamboo packaging device is frequently Situated around the manufacturing ground alone and it creates prolonged strips of bamboo for Bamboo Intercontinental's buyers. This device also has a considerable-scale cutter that is utilized to cut the bamboo into blocks with the creation of Bamboo chopsticks.

The final equipment on the Bamboo chopsticks output line is known as the significant-scale ending machine. This equipment cuts the bamboo into strips just right before They may be delivered to be packaged into Bamboo chopsticks. The equipment will then polish the bamboo items right before shipping and delivery them to The purchasers. This machine is powered by an electric motor and it's accustomed to speedily complete every one of the bamboo manufacturing course of action. The device may also help in making sure that the bamboo is Slash into uniform strips for proper packaging.

These are definitely different equipment which might be found in the Bamboo chopsticks creation. Every single machine has its personal use and it is up into the discretion of the Bamboo makers on how they might make the most of them. The automatic domestic bamboo chopstick building machine is not really that onerous to implement as it only can make positive that all the measures are effectively done and there is no home for mistake as the many devices are automated.

In addition to these domestic machines, There exists also a large production line for Bamboo chopsticks exterior the manufacturing unit. The creation line can make Bamboo chopsticks in bulk. There are even some locations where by Bamboo chopsticks are created on an industrial scale. These areas deliver Bamboo sticks for your car producing industry, hotels, hospitals as well as other industries. Bamboo sticks are frequently favored in excess of plastic chopsticks considering that they final more time and are more sturdy. If you wish to get Bamboo chopsticks, you need to look into the Bamboo sticks manufacturing facility during the factories place or try and check with the workers straight.

An additional kind of device which can help in producing Bamboo chopsticks is the automatic picket bamboo sticks chopper. Such a machine is usually utilized for the automatic paper slicing machines. A worker will manually set the extent of your paper feed charge. At the time this is set, the chopper will immediately slice the bamboo sticks into consistent lengths determined by how many pieces of paper are getting used.

In relation to the manual creation of bamboo chopsticks, it mainly just calls for chopping bamboo sticks In keeping with the necessities of the manufacturer. On the other hand, there are still a number of things that must be checked when it comes to the caliber of bamboo sticks in advance of They may be despatched for the factory. The bamboo adhere need to be clear and totally free from any splinters. Bamboo chopsticks are Usually coated with a lacquer that forestalls sharp objects from embedding them selves into them. The producer also ought to check on the bamboo sticks and Test whether it is the right way fitted and evenly sized so that it's going to search just how it truly is developed.